Polyolefin (POF) Shrink Films

Polyolefin (POF) shrink films are crafted to offer robust protection, catering to a wide spectrum of products, from hefty items to those with distinct shapes. These films are known for their versatility, encompassing enhanced merchandising appeal, exceptional product protection, and the maintenance of pack integrity through comprehensive wrapping.

Unlocking packaging potential with POF shrink films

- Premium quality POF shrink film with high clarity and gloss

- Ecofriendly sustainable packaging solution, made from 100% recyclable materials

- Excellent durability, versality & cost-effective

- Cross-linked POF shrink film is a superior choice for high-speed applications

- FDA approved for food contact

- Wide sealing window delivering excellent seal and shrink integrity

- Good tear resistance provides a safe & durable wrap on products

- High burnout resistance

- Compatible with all Shrink Wrap machines

- High tensile strength makes it an excellent choice for product bundling without ‘dog-ears’

- Operator friendly

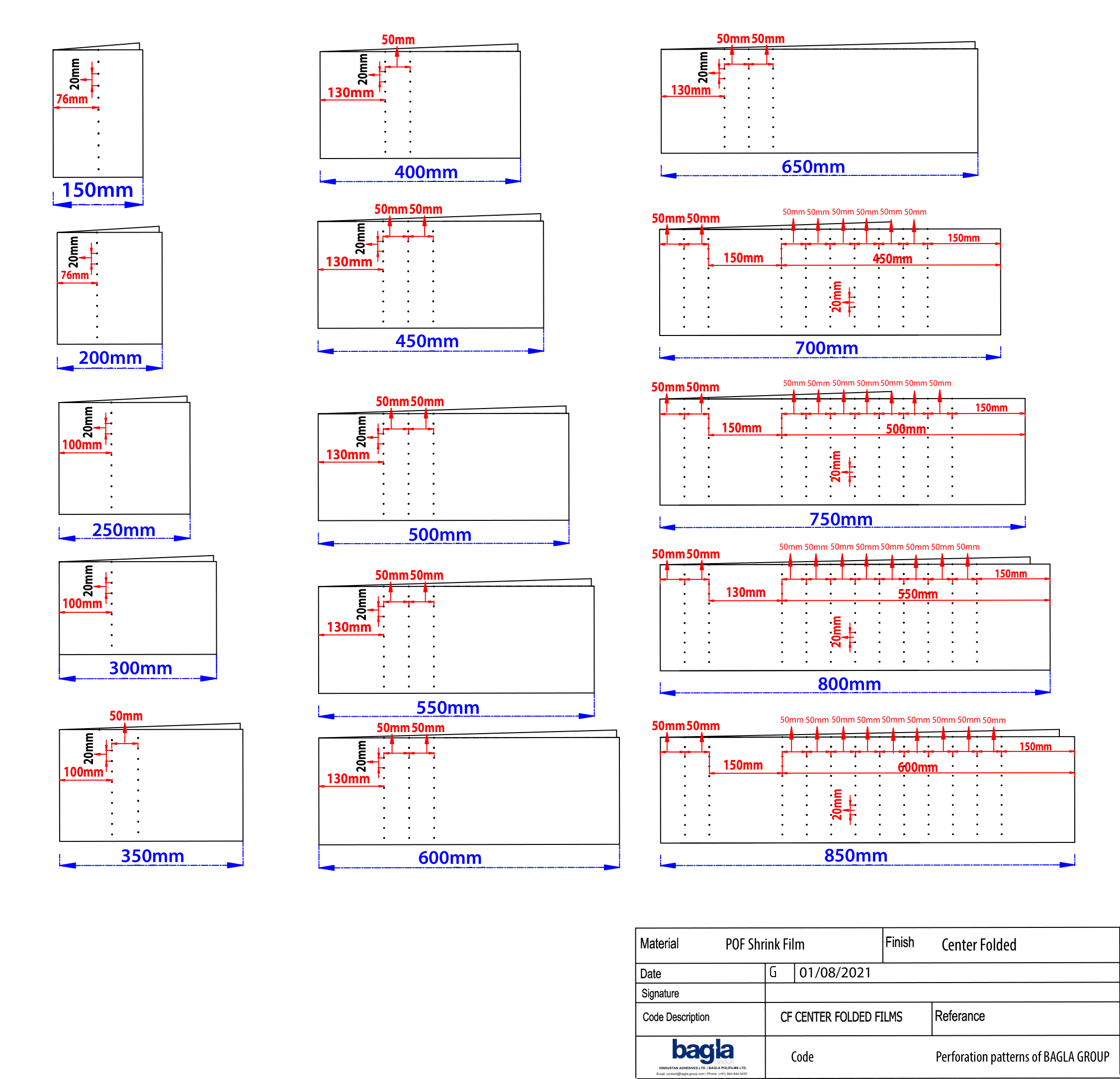

- Pre-perforated POF shrink films also available, say no air pockets!

- High definition printing capabilities, in upto 8 colors

Cross Linking Technology

The innovative technique of cross-linking’ yields highly durable and versatile Shrink Films due to the permanent and stable bonds created between the polymer chains ensuring complete protection of the various products.

What makes Polyolefin(POF) Shrink film are preferred choice in packaging industry

- Polyolefin (POF) shrink film is primarily composed of polyolefin resins, which are synthetic polymers derived from petrochemical sources. LDPE and LLDPE are commonly used because of their excellent film-forming properties and flexibility.

- Polyolefin resins used in POF shrink film have an amorphous or non-crystalline structure. This means that the polymer chains are randomly arranged, which results in a transparent and flexible film

- To facilitate the shrinkage process, various additives are incorporated into the polyolefin resin mixture. These additives include heat stabilizers, processing aids, and slip agents. Some Polyolefin (POF) also contain anti-fog additives to reduce moisture condensation.

- The key feature of Polyolefin (POF) shrink film is its ability to shrink when exposed to heat. This results in the film contracting or shrinking in both the MD and TD, tightly conforming to the shape of the product being packaged.

- The extent of shrinkage, known as the "shrink ratio," can be controlled during the film manufacturing process. Polyolefin (POF) shrink films with different shrink ratios are available to suit various packaging needs.

- Polyolefin (POF) shrink film also possesses excellent sealing properties, allowing for strong, airtight seals that help maintain product freshness.

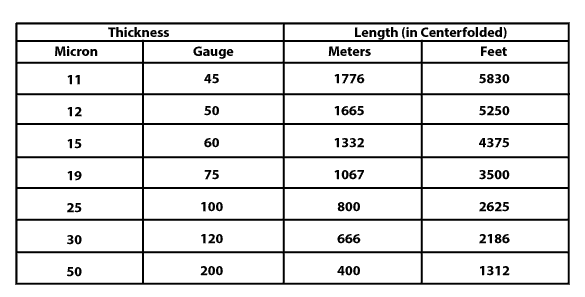

We offer a wide range of POF Shrink Films

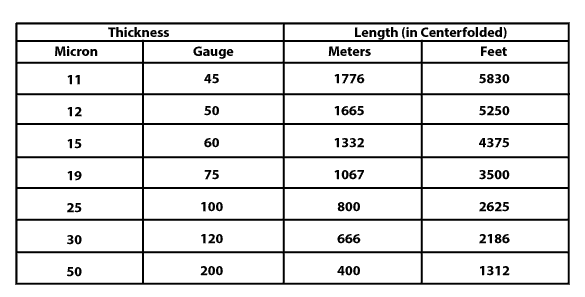

Center Folded

Single Wound

Pre-perforation available

Pouches

Printable